Change Language :

Inspection and test technology

Overview

Optical inspection by cameras or sensor detection is used in filling systems to check the containers passing through and divert them if necessary. Camera, sensor and lighting technology must be flexibly adjustable for this purpose. This is where our linear bearing technology comes into its own, ensuring the smooth and continuous fine adjustment of expensive technology without the use of lubricants.

Products used and application examples

Using the example of Indspect GmbH's testing devices, the testing technology in bottling plants is discussed in more detail. Our products such as linear bearings or spindle linear tables are primarily used here for the precise adjustment of sensors, cameras and lighting technology.

Customer application examples

Format adjustment in inspection systems

Inspection systems from Krones such as the Linatronic 735 rely on our plain bearings, e-chain®, gearbox solutions and linear axis for format adjustment.

Go to user report

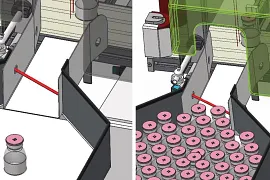

Bottle sorting

Tribo-Tape sliding film made of iglidur® W160 reduces the frictional resistance in this bottling line to a minimum.

Go to user report

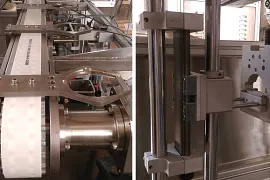

Optical inspection in conveyor technology

lubrication-free linear bearings move camera and lighting systems for the optical inspection of pharmaceutical products.

Go to user report

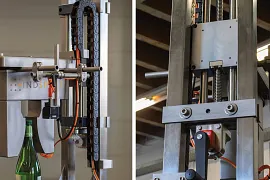

Inspection device

Linear plain bearings in Indspect's inspection devices enable food-safe inspection for the beverage industry.

Go to user report

And even more...

Discover even more successful applications in the beverage, food and packaging industries.

Discover more applicationsConsulting

I look forward to answering your questions

International company for Electrical Engineering, I.E.E. (Non-port business)+201144146285Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr