Change Language :

FDM printing process: Customised production for your requirements

The FDM printing process has become one of the key technologies in 3D printing - but what is actually behind it?

Fused deposition modelling (FDM) enables the production of physical objects by processing molten plastic filament layer by layer. This process is also known as fused filament fabrication (FFF).

FDM printing can be used in many areas, from industrial prototypes to hobby applications, as the process combines ease of use with versatility.

igus offers users of the FDM printing process specially developed filament made from high-performance plastics for processing on standard 3D printers. These materials are more durable than conventional plastics and are ideal for wear-resistant parts in moving applications.

Discover on this page:

Where is the FDM printing process used?

Fused deposition modelling is used as a manufacturing process for components in many different areas of application, including:

Filling and packaging machines: For example, for individual product turners on conveyor belts

Prototyping: For rapid test series and design developments

Mechanical engineering and plant engineering: Tools, devices, replacement of milled plastic parts

Aerospace: Lightweight and complex geometries for simulations or test components

Automotive industry: Functional prototypes, brackets and small batches

Medical technology: Customised models and prototypes for surgical planning

Hobby & DIY: Applications such as jewellery design, model making and decorative household objects

FDM printing in practice

Maintenance-free grippers from 3D printing

Carecos Kosmetik GmbH needed production grippers that grip lids and screw them onto containers. Previously, these were milled from aluminium, which was associated with costs of up to 10,000 euros per gripper and a production time of six weeks. Thanks to the tribologically optimised iglidur i150 3D printing filament, igus was able to deliver a quick and cost-effective solution. The plastic grippers are lighter, up to 50 times more wear-resistant and can be printed within 10 to 12 hours. The result: 85% cost savings and 70% faster production. Ideal for flexible production in a wide range of industries.

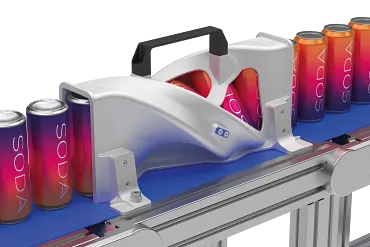

Product turner made of iglidur i150 for beverage filling

In the beverage industry, product turners were previously made from steel wires or milled blocks of material, which involved high costs, a lot of material waste and long delivery times. igus developed a 3D-printed alternative made from iglidur i150 filament. The printed can turner has a special spiral-shaped structure that turns cans precisely and prepares them for error-free filling. The component offers the same functionality as the previous solution, but reduces production costs by up to 70%. It enables the processing of up to 60,000 cans per minute, is maintenance-free and its design can be flexibly adapted to any can size.

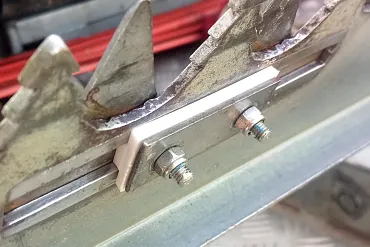

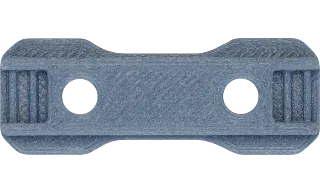

Gliders for floating mowers

Floating mowers remove grasses from lake shores. Their cutting blades were tensioned with metal gliders, which quickly wore out due to dirt and moisture and were replaced three times per season. Replacement parts were very expensive. With 3D-printed glides made of iglidur i180, a robust, cost-effective alternative was created. The components are up to 15 times more cost-effective, 50 times more abrasion-resistant and operate lubrication-free thanks to the solid lubricants they contain. FDM 3D printing also enables fast and flexible delivery, which significantly reduces maintenance requirements and overall costs.

Working together to find the best solution for your project

Which manufacturing process is best suited to your requirements?

We'll find out together! Our experts will advise you personally and will be happy to help you choose the ideal solution for your individual application.

Advantages of the FDM printing process

When it comes to fast results and easy handling, the FDM process is a tested and proven choice:

- Versatile choice of materials: In addition to standard plastics such as PLA and ABS, which are also used in injection moulding, high-performance polymers can also be used. igus offers a wide range of wear-resistant plastics, including food-safe, chemical-resistant and heat-resistant materials.

- Multi-colour printing and multi-material capability: With FDM, different filaments can be combined in one printing process to print components with different specifications.

- Ease of use: The simple operation of most 3D printers makes the process particularly attractive for beginners.

- Fast production: Small components are printed quickly - ideal for prototypes and small batches.

- Cost efficiency: FDM printers are often more cost-effective to buy and operate than other systems. The materials are inexpensive and readily available, which keeps operating costs low. The method also impresses with a clean process - without any protective equipment or additional devices such as ultrasonic cleaners.

Limits of FDM printing

Although the FDM printing process is very versatile, the process reaches its limits in certain areas:

- Lower level of detail: Visible layer lines and reduced precision compared to processes such as SLA or SLS.

- Post-processing: Support structures and layer lines may require additional processing, e.g. grinding or painting, depending on the surface quality requirements.

- Limited production volume: FDM is less economical for series production. For large quantities, the injection moulding process offers clear advantages in terms of speed and costs per component.

When does each procedure make sense?

Sometimes complex geometries, higher levels of detail or exceptionally resilient components require a different 3D printing technology. igus offers a 3D printing service for customised components using the FDM, SLS and DLP processes. ⯈ Learn more about the 3D printing service

The following table compares FDM printing with these other technologies:

| Criterion | FDM | SLS | DLP |

|---|---|---|---|

| Dimensional stability | Less accurate | Exactly | Very accurate |

| Surface quality | Visible layers | Smooth, hardly any layer lines | Very smooth |

| Mechanical properties | Higher anisotropy in strength, fibre-reinforced material available | Only slight anisotropy | Very homogeneous structure, isotropic strength |

| Complex shapes possible? | Restricted, support structures necessary | Very good, no support structures required | Very good, fine details possible |

| Print duration | Fast for individual items | Fast with higher quantities | Fast with higher quantities |

| Cost | Cost-effective | Medium-priced | Rather higher costs |

| Special features at igus | Large components, multi-material printing possible | High-volume production, high dimensional accuracy | Extremely fine details possible |

Additional explanations

Anisotropy describes the direction-dependent specifications of a material.

In FDM printing, the layered structure results in differences in stability, particularly between the printing plane (X/Y) and the vertical direction (Z).

In the Z direction, the component often has a lower strength due to weaker layer adhesion.

As a consequence, the orientation of the component should be selected so that the load is in the more stable direction as far as possible.

Isotropy means that a material reacts in the same way in all directions - regardless of the direction of loading.

In FDM printing, this is not a given by nature, as the layers are bonded together differently. Optimised printing parameters and targeted alignment help to promote isotropic behaviour.

Materials for FDM printing

The right choice of material determines the performance of a 3D-printed component. In FDM printing, the spectrum ranges from easy-to-process standard filaments to high-performance plastics that fulfil even the most demanding requirements.

Wear-resistant igus tribofilament

POM, PE and PA impress with good sliding properties and dimensional stability, but are difficult or even impossible to process in 3D printing. igus offers an easy-to-process alternative to these plastics with its iglidur filaments. For applications where conventional engineering plastics reach their limits, for example with permanently moving parts or high friction, igus offers various filaments with exceptionally high wear resistance. Discover the extensive range, from easy-to-process all-rounders to solutions for demanding application conditions.

How does the FDM printing process work? A look at the technology

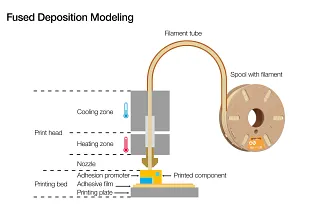

The FDM printing process works according to a simple principle: Heated plastic filament is melted and extruded layer by layer until the object is completely built up.

- Material feed: The plastic filament is unwound from a spool and fed evenly into the print head of the 3D printer.

- Material processing: The filament is heated in the print head - to temperatures between 190°C and 450°C, depending on the material - and released in molten form as a fine strand (extruded).

- Layer structure: The print head moves precisely along the paths specified by the 3D model and applies the molten material layer by layer. Rapid cooling causes the plastic to solidify immediately and the individual layers bond together. This is how the component is created step by step.

What is important when planning FDM printing

Good planning is the key to successful FDM printed parts. Below you will find the most important points for ideal preparation.

Typical challenges in FDM printing

What can you do as a user if the processing of filament does not run smoothly and the desired result does not materialise? For the following two challenges and many other problems with 3D printing with filament, we offer you tips and assistance for problem solving in our guide. ⯈ Download here

Want more?

Benefit from our "24 tips for 3D printing with filament"

Some problems with 3D printing with filament are easy to recognise and solve, others are more complex and can have multiple causes. Would you like to know how to effectively solve typical challenges in FDM printing? Then download our guide now and get tips to optimise your print quality!