My contact person

e-chains®, chainflex®, cables, harnessed systems readychain®

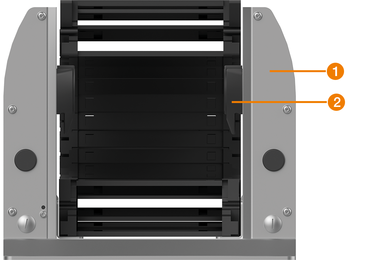

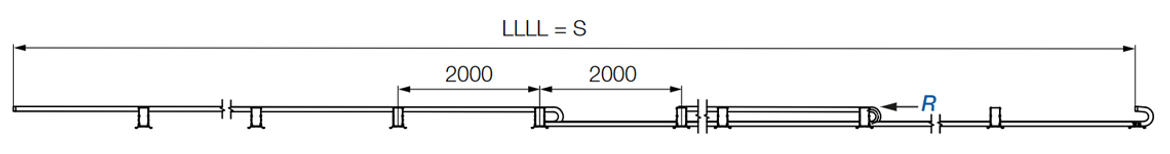

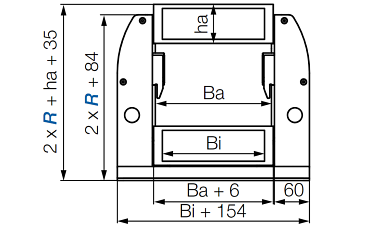

| Part No. Support plate | Part No. e-chain series | Inner width [mm] | Bend radius [mm] | Support gap [mm] | |

|---|---|---|---|---|---|

| GLO.CR.56.R | E6.52 | 50 - 300 | 075 - 250 | 1,000 - 2,000 |  Request now Request now |