Change Language :

Energy chains, cables and bearings for construction machinery

More powerful in use, without lubrication

This saves Huppenkothen 220 maintenance cycles per excavator.

"GO ZERO". A new study by RWTH Aachen University shows that polymer bearing technology can save customers not only expensive greases and oils, but also labour costs ... and maintenance cycles, as the case of Huppenkothen now shows.

Areas of application

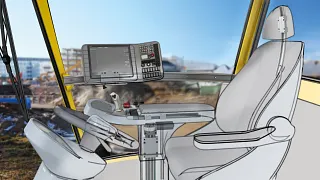

motion plastics for vehicle cabins

Linear guides, plain bearings, energy chains, linear axes and more

Maintenance-free bearing products can be used to reliably adjust seats and displays or mount master switches. If they are electrically adjustable, our compact e-chain together with chainflex cable ensure a safe and quiet energy supply.

More information

Heavy-duty brochure

All important information about our igutex plain bearing products and services

Download now

Online tools

Configure your desired product online, calculate service life, bring process cost down

Discover toolsConsulting

I look forward to answering your questions

International company for Electrical Engineering, I.E.E. (Non-port business)+201144146285Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr