Change Language :

Our test laboratory for iglidur® plain bearings

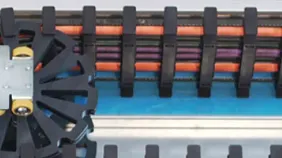

With their tribological specifications, our plastic plain bearings fulfil the highest requirements for a long service life without additional lubrication. To achieve this quality, we carry out over 135 trillion test movements per year in our 250 m² plain bearing test laboratory. We test and develop materials and plain bearings under real conditions with the aim of delivering the best plastic solution for your application. The polymer bearings are optimised for use in motion and open up new scope in design with their specifications. Base polymers, solid lubricants and reinforcements are combined in such a way that the characteristics of the plain bearing required for the application are fully achieved. The tests focus on tensile and shear forces, coefficient of friction, wear as well as abrasion and drive force under different speeds and loads of the bearing.

What is tested and how?

In the iglidur® and igubal® test area, bearings and materials are tested for stress, wear and friction properties. Other parameters such as high and low temperatures, high load and speed are adjusted depending on the test. There are around 50 test systems in the test laboratory, on which more than 300 parallel tests are carried out. At the same time, we carry out around 11,300 tribological tests on the 250 or so newly developed plastic compounds every year. To ensure that the new formulations prove themselves in later use, they are not only exposed to external influences, but also to different directions of movement and loads - rotating, swivelling, linear, walking.

We also test our components for the effects of dirt, weather conditions, impacts and shocks. The results of our tests are stored in databases and incorporated into our online tool.

Which test stands are available in the plain bearing test laboratory?

We would love to test your application

Do you want to avoid experimenting and subject your application to a material test before use? Or do you have an unusual application for which a suitable solution needs to be found? No problem. We will test your application in our test laboratory and use our expertise to find the best igus® solution for you. Regardless of whether it is a plain bearing, energy chain, cable, linear technology, bar stock, guide rollers or Low Cost Automation.

Enquire now!

The different areas of the igus® test laboratory

Consulting

I look forward to answering your questions

International company for Electrical Engineering, I.E.E. (Non-port business)+201144146285Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr